This 8-hour course is designed to provide the food, beverage and natural product manufacturing industry with a comprehensive understanding of developing, and implementing impactful and appropriate Environmental Monitoring Plans (EMPs). The course will cover the importance of microbial and allergen controls, public health, sanitation, sanitary facility design, and good personnel training and hygiene and how it all relates to a successful environmental monitoring program. We will review different types of testing and how to interpret results.

Food and beverage quality assurance professionals, regulatory affairs personnel, auditors, and anyone involved in implementing or managing wet or dry food production.

- Why should food manufacturing facilities have an environmental monitoring program?

- Developing an environmental monitoring program

- Implementing an environmental monitoring program

- Sanitary facility design

- Personnel & Training

- What are we testing for? Pathogens, ATP, allergens, spoilage organisms

- Tracking and trending data

- Benefits of a good EMP

- Facility Considerations

- Tools & Timing Considerations

- Results and Record Keeping

- Validation

- Reviewing your Environmental Monitoring Program

- Understand the purpose of an environmental monitoring program

- Determine if an environmental monitoring program is necessary for your facility and, if so, how to develop and implement one

- Recognize the importance of sanitation, sanitary facility design, and good personnel training and hygiene and how it all relates to a successful environmental monitoring program

- Understand the importance of microbes, food-borne pathogens, allergens, and ATP in a manufacturing setting

- Understand how environmental monitoring relates to public health and product quality and how it benefits your business

- Identify different types of environmental monitoring tests and sampling

- Interpret and organize data and monitor results

Group exercises include:

- Activity 1: Rank These Facilities

Participants will be given a list of manufacturing facilities with short descriptions regarding what the companies make and some of their practices. They will then be asked to rank the facilities in order of who needs an environmental monitoring program the most to who needs one the least. - Activity 2: Glo-Germ (This activity can be modified if class is to be taught in a virtual setting)

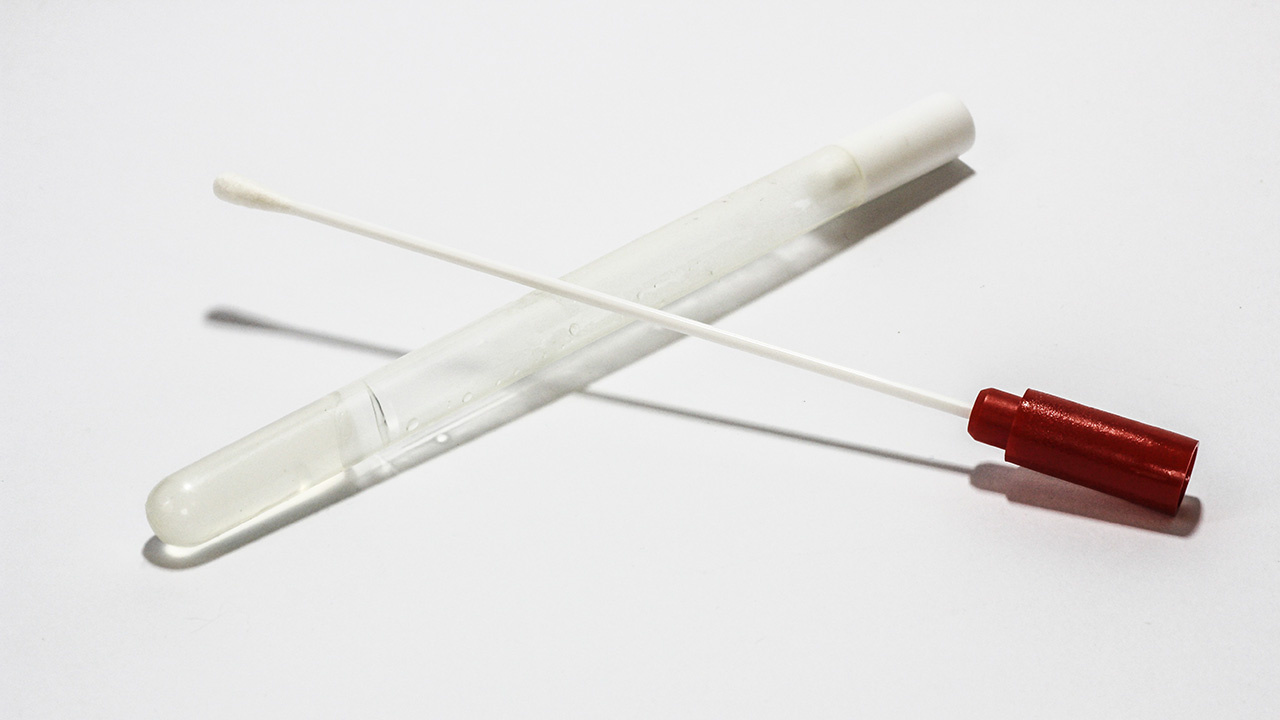

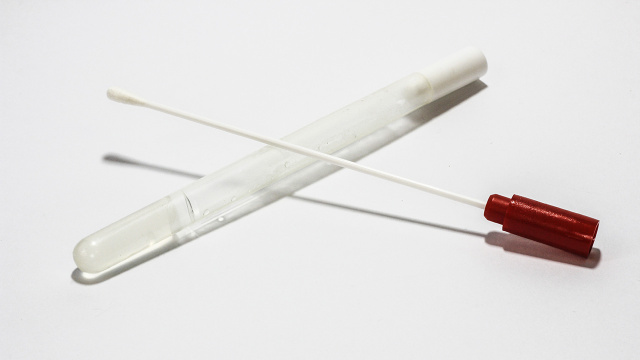

Participants will be given instructions on how to apply glo-germ to a specific piece of equipment and then will be asked to move the object around the room and among people. We will then use a blacklight to track the movement of the “germs”. - Activity 3: Using a Luminometer (This activity can be modified if class is to be taught in a virtual setting)

Participants will be given detailed instructions on how to swab and use the Hygiena luminometer. They will then be allowed to choose a location in the training room to swab and test for ATP residues. - Activity 4: Data Interpretation

Participants will be given a spreadsheet containing different types of environmental monitoring data. Using what they’ve learned so far, they will be asked to identify potentially concerning data, will learn about problems commonly associated with records, and will help them learn how to identify trends as well as how to interpret data. - Activity 5: ELISA Test (This activity can be modified if class is to be taught in a virtual setting)

Participants will observe an ELISA-based allergen environmental monitoring technique/test. - Activity 6: Data Interpretation

Participants will be given a spreadsheet containing different types of environmental monitoring data. Using what they’ve learned so far, they will be asked to identify potentially concerning data, will learn about problems commonly associated with records, and will help them learn how to identify trends as well as how to interpret data. - Activity 7: Facility Layout

Participants will be given the “bones” of a food manufacturing facility and will be asked to arrange the items they’re given in a way that incorporates what they’ve learned about the importance of sanitary design and flow. - Activity 8: Hygienic Zoning

Participants will be given the layout of a potato chip manufacturing company. As a group, they will be asked to identify zones 1, 2, 3, and 4 based on what they’ve learned about hygienic zoning so far and will be asked to identify the best flow of traffic with regards to people, materials, products, visitors, etc.

Delivered online with a live instructor at a scheduled date and time.

This 8-hour course is designed to provide the food, beverage and natural product manufacturing industry with a comprehensive understanding of developing, and implementing impactful and appropriate Environmental Monitoring Plans (EMPs). The course will cover the importance of microbial and allergen controls, public health, sanitation, sanitary facility design, and good personnel training and hygiene and how it all relates to a successful environmental monitoring program. We will review different types of testing and how to interpret results.

Food and beverage quality assurance professionals, regulatory affairs personnel, auditors, and anyone involved in implementing or managing wet or dry food production.

- Why should food manufacturing facilities have an environmental monitoring program?

- Developing an environmental monitoring program

- Implementing an environmental monitoring program

- Sanitary facility design

- Personnel & Training

- What are we testing for? Pathogens, ATP, allergens, spoilage organisms

- Tracking and trending data

- Benefits of a good EMP

- Facility Considerations

- Tools & Timing Considerations

- Results and Record Keeping

- Validation

- Reviewing your Environmental Monitoring Program

- Understand the purpose of an environmental monitoring program

- Determine if an environmental monitoring program is necessary for your facility and, if so, how to develop and implement one

- Recognize the importance of sanitation, sanitary facility design, and good personnel training and hygiene and how it all relates to a successful environmental monitoring program

- Understand the importance of microbes, food-borne pathogens, allergens, and ATP in a manufacturing setting

- Understand how environmental monitoring relates to public health and product quality and how it benefits your business

- Identify different types of environmental monitoring tests and sampling

- Interpret and organize data and monitor results

Group exercises include:

- Activity 1: Rank These Facilities

Participants will be given a list of manufacturing facilities with short descriptions regarding what the companies make and some of their practices. They will then be asked to rank the facilities in order of who needs an environmental monitoring program the most to who needs one the least. - Activity 2: Glo-Germ (This activity can be modified if class is to be taught in a virtual setting)

Participants will be given instructions on how to apply glo-germ to a specific piece of equipment and then will be asked to move the object around the room and among people. We will then use a blacklight to track the movement of the “germs”. - Activity 3: Using a Luminometer (This activity can be modified if class is to be taught in a virtual setting)

Participants will be given detailed instructions on how to swab and use the Hygiena luminometer. They will then be allowed to choose a location in the training room to swab and test for ATP residues. - Activity 4: Data Interpretation

Participants will be given a spreadsheet containing different types of environmental monitoring data. Using what they’ve learned so far, they will be asked to identify potentially concerning data, will learn about problems commonly associated with records, and will help them learn how to identify trends as well as how to interpret data. - Activity 5: ELISA Test (This activity can be modified if class is to be taught in a virtual setting)

Participants will observe an ELISA-based allergen environmental monitoring technique/test. - Activity 6: Data Interpretation

Participants will be given a spreadsheet containing different types of environmental monitoring data. Using what they’ve learned so far, they will be asked to identify potentially concerning data, will learn about problems commonly associated with records, and will help them learn how to identify trends as well as how to interpret data. - Activity 7: Facility Layout

Participants will be given the “bones” of a food manufacturing facility and will be asked to arrange the items they’re given in a way that incorporates what they’ve learned about the importance of sanitary design and flow. - Activity 8: Hygienic Zoning

Participants will be given the layout of a potato chip manufacturing company. As a group, they will be asked to identify zones 1, 2, 3, and 4 based on what they’ve learned about hygienic zoning so far and will be asked to identify the best flow of traffic with regards to people, materials, products, visitors, etc.